Enhancing Gas Turbine Maintenance with Dry Ice Blasting

Recently, we seized the opportunity to employ dry ice blasting within a liquefied natural gas-powered electricity generation plant boasting a capacity of approximately 204MW. This combined cycle setup consists of three LNG-fired 50MW gas turbines, a HRSG, and one 50MW steam turbine.

Each gas turbine underwent maintenance, prompting us to address the cleaning requirements for the compressor-side blades and a set of loose blades in one of the gas turbines.

The observed contamination manifested as a reddish patina, likely stemming from pollutants present in the inlet air and potentially exacerbated by nearby sea-related salinity.

Dry ice blasting emerged as a superior cleaning method, offering enhanced efficiency and quality while adequately preparing the blades for non-destructive inspection via dye penetrant methodology. The process entailed cleaning the compressor-side rotor blades over a single working day, utilizing a maximum of 120kgs (3mm pellets) of dry ice.

Subsequently, we tackled a set of loose blades, also afflicted with the reddish patina and a thin film of oily residue. Employing another 120kgs of 3mm dry ice pellets, this task was accomplished within a similar timeframe.

The outcomes were exceedingly positive, receiving validation from the units’ OEM. Dry ice blasting's primary advantage over conventional manual methods—utilizing cloths, brushes, and solvents—lies in its efficiency and cleaning quality, with virtually no risk of surface damage. This high-quality cleaning is paramount for the accurate execution of non-destructive inspections.

Moreover, dry ice leaves no residual matter, eliminating the risk of secondary contamination and the need for additional shielding against ancillary pollutants. The absence of solvents or abrasive media reduces health and safety hazards for operators, along with negating the necessity for costly waste disposal procedures.

These successes pave the way for future dry ice blasting requirements for the remaining gas turbines slated for subsequent maintenance.

Equipment Utilized:

Air Compressor:

Atlas Copco electrically driven 5cbm capacity screw compressor with aftercooler and air dryer.

Dry Ice Blaster:

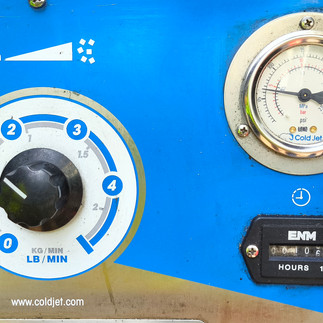

Cold Jet AERO40 dry ice blaster equipped with:

1” air hose

1” blasting hose and applicator

Round nozzle diam. 11mm – compressed air capacity: 1.8m3/min @5.5 bar

Adopted Parameters:

Dry Ice Consumption: 0.5kgs/minute

Dry Ice Blaster Regulated Blasting Pressure: 4 bar up to 5 bar

Total Dry Ice Requirement: 240kgs

.png)

Comments